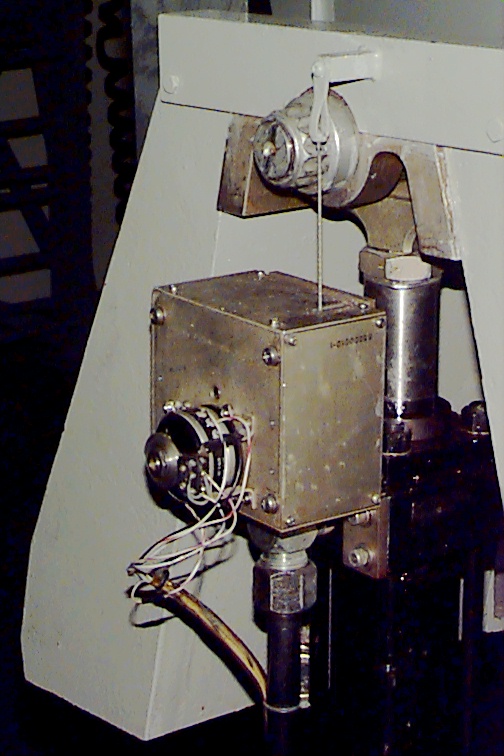

This is closeup of the positioner feedback pot. There is one just like it on the right actuator frame and the center actuator frame in the rear middle.

This is closeup of the positioner feedback pot. There is one

just like it on the right actuator frame and the center actuator frame

in the rear middle.

The wire coming out of the top is just a plastic coated wire rope.

It winds around a spring driven wheel that's in

turn mounted to the 10 turn precision potentiometer mounted on the

side of the box. This is how the computer

knows what position the actuator is currently in. Much fun can

be had if you walk by the sim while a flightcrew

is using it, and "strumming" the line. The result is the simulator

cab will "kneel" in the side you pull the line on.

Problem is, the video then no longer matches the slant of the flight

deck and the crew begins to turn green if you

persist in fiddling with it. :)

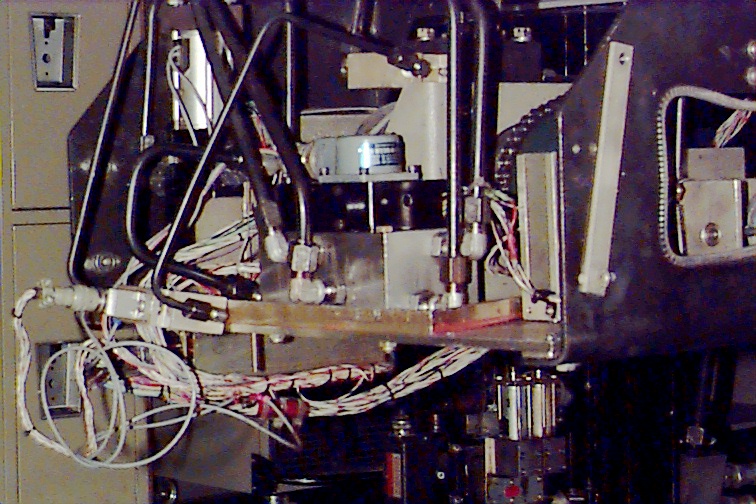

This is a picture of the center actuator, located in the rear of the

simulator cab, dead center.

The C/M 737-200 simulator is known as a 3-Axis system. It only

has three motion points (left, right and "heave" provided by the actuator

shown here).

Since this simulator was manufactured in 1967, it only operates now

due to a grandfather clause in the FAA regulations. The simulator

only provides nighttime levels of exterior illumination and the systems

response is

within the 300ms reaction time as specified by the Class A certification

guidelines. Most of the motion enabled commercial flight simulators

in use today are known as Class D. This means they've got a hexapod

[see Simulator Tour for images and

more details on a hexapod] configuration motion system, a 150ms systems

response maximum and full daylight illumination video, usually spanning

a greater than 130 degree field of view.

If you look to the right of the gray can with the blue label, you'll

see a curved, bumpy shape. This is the chain

and sprocket that connects the electric trim system to it's motor.

This mechanism is described on the 727 CPT

pages.